Rebar Rolling Mill Line

- Category:Rebar Rolling Mill Line

- Intro:

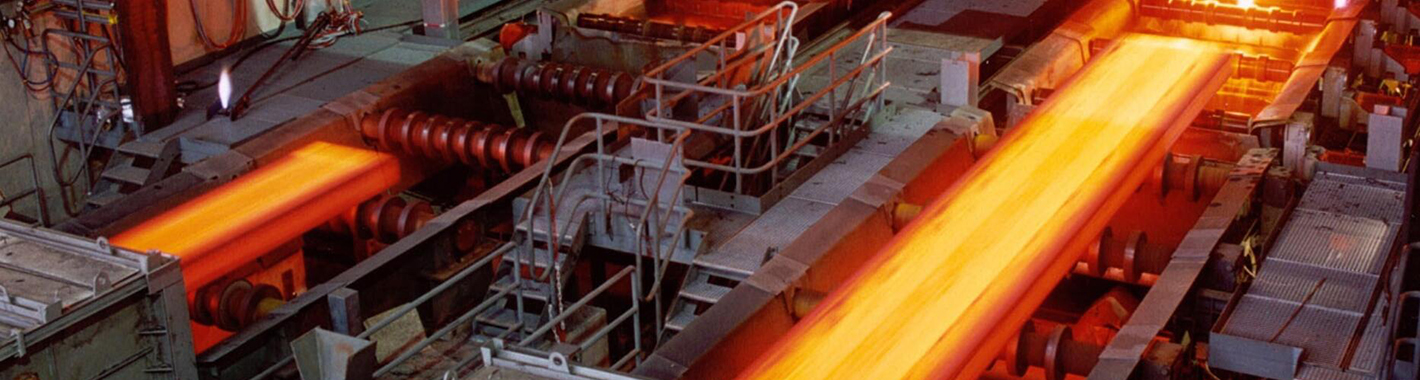

Rebar rolling mill production line

The rebar making process can be as following:

Qualified billets--Reheating--rolling mill --cutter for size---cooling bed---cutting ----quality checking----package----weighting-----warehouse

The rebar size normally from φ10/φ12/φ14/φ16 until to 32mm.

We can design directly rolling from roughing to finished rolling mill, will use DC motor control, easy to test and operate.

If make rebar capacity as 200,000T per year, the machine supplying list can be as following

| NO | name | Qty | Unit |

| 1 | ф450 three roller roughing rolling mill | 1 | set |

| 2 | ф325 two roller rolling mill(with mill connection channel) | 12 | stand |

| 3 | TMT system | 1 | set |

| 4 | 3# fly shear | 1 | set |

| 5 | Automatic cooling bed | 1 | set |

| 6 | packing platform system | 1 | set |

| 7 | hydraulic cutter | 1 | set |

| 8 | AC&DC driving system and electricity control box | 1 | set |

Rebar Rolling Mill Line

First rolling mill is roughing rolling mill, it is mainly to reduce the input steel billets size,

and extend its length, roughing rolling mill is important machine for whole line,

we have three roughing rolling stand and two roller directly rolling mill stand.

It is with reducer, gear box and so on, normally with AC motor 1250KW.

Work process design

The hot rolling mill work process is based on the latest technologies

Rolling mill pass design

The roll pass design is for high productivity and efficient production.

Technical solutions development

The engineering of the best rolling mill plant solution for full customer satisfaction.

Automatic system

PLC control is for rebar rolling mill whole line system