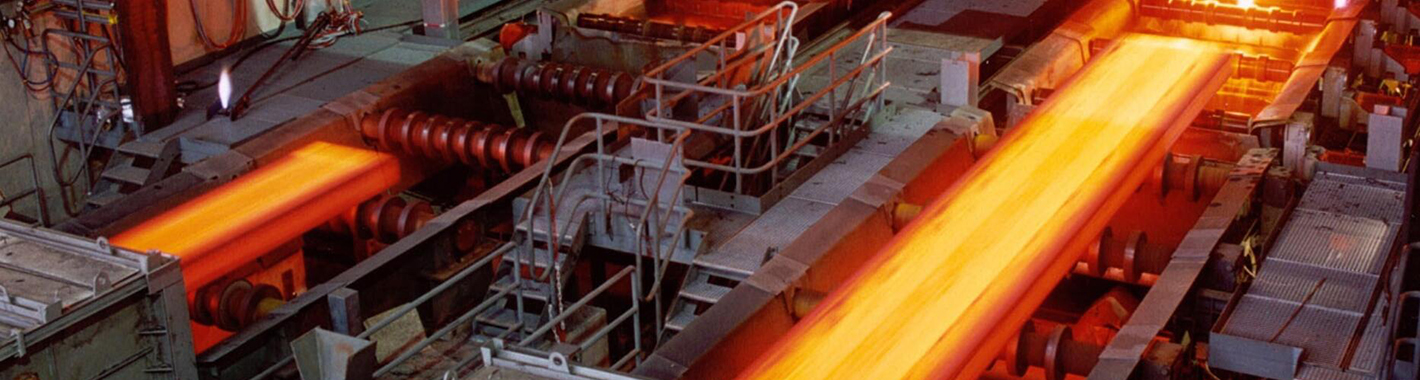

what is the rolling mill rolling process

What is rolling process? Rolling is a metal forming process, in which stock of material is passed between one or more pairs of roller to reduce and maintain the uniform thickness. Rolling process has hot rolling and cold rolling. Now what is hot rolling? The rolling process in which metal to be passed between the rollers is heated above its recrystalization temperature then the process is known as hot rolling. And obviously, If the temperature of metal to be passed between the rollers is less than its recrystallization temperature then the process is known as cold rolling. Let us focus one the rolling for rebar production, Two high rolling mill Three high rolling mill

Let us discuss all the rolling mills one by one. First is two high rolling mill. This is the simplest type of rolling mill setup, in which two rollers are used. The distance between two rollers can be adjusted according to the metal thickness. The lower roller is fixed, whereas upper roller has vertical motion to adjust the distance between two rollers. This type of rolling mill known as non reversing rolling mill. The two rollers will exert large amount of pressure on the stock and forces out to the right side, which results in decrease in the thickness of metal stock. Due to the direction of rotation of two rollers, we are unable to feed ingot from right side, so it is known as non reversing rolling mill.

Feeding of metal stock from right side is also possible, provided that there should be arrangement of changing the direction of motion of the roller. It means, in reversing mills we can feed metal stock from both sides. The reversing mills are used to increase the productivity.

Next type of rolling mill is three high rolling mill. In this type of rolling mills, three rollers are used one over the other in a vertical line. We can pass the steel billets between first two rollers and then last two rollers. Please remember, direction of rotation of first and last roller is always same in this type of rolling mill. This type of arrangement has higher rate of production than the two high rolling mill because we can pass two metal stocks at a time. Four high rolling mill. This setup is very much similar to two high rolling mill. But in this mill instead of two rollers, Four rollers are placed in a vertical line. But the size of all rollers is not same. The two rollers which comes in contact between metal stock, have the same size and the other two have same size. The big rollers are used for backup purpose only. Small rollers will exert pressure on metal stock and thickness of material will get decreased. Rate of decrement is more in this case as compared to other two cases which we have discussed above and specially this rolling mill is used in case of rolling of hard materials. Next is cluster rolling mill In this type of rolling mill, two or in some cases three backup rollers are used to reduce the thickness of hard material. The following point is very important point about the rolling mill, If we talk about the material, its volume remains constant in all the cases but only change in shape and size takes place. We can see in the picture, length of the metal stock is less before passing through the rollers, but after rolling operation, length increases and thickness of ingot decreases or in other words, length is inversly proportional to thickness of the material. And the last is tandem rolling mill. In this type of rolling mill, metal stock is continuously passing through the different pairs of rollers, so that we can obtain the desired shape and size of the component in one pass only. Thanks and regards,